Single medium (water, oil, air) quenching: Quenching a workpiece that has been heated to the quenching temperature into a quenching medium to completely cool it. This is the simplest quenching method and is commonly used for carbon and alloy steel workpieces with simple shapes. The quenching medium is selected based on the size of the heat transfer coefficient, hardenability, size, shape, etc. of the part.

2、 Double medium quenching

Double medium quenching: The workpiece heated to the quenching temperature is cooled to near Ms in a quenching medium with strong cooling capacity, and then transferred to a slowly cooled quenching medium to cool to room temperature to achieve different quenching cooling temperature ranges, with a relatively ideal quenching cooling rate. This method is also commonly used for large workpieces made of complex shapes or high carbon steel or alloy steel, and for carbon tool steels. Commonly used cooling media include water oil, water nitrate, water air, and oil air. Generally, water is used as a fast cooling quenching medium, while oil or air is used as a slow cooling quenching medium, with less use of air.

3、 Martensitic step hardening

Staged martensite quenching: A quenching process in which steel is austenitized and subsequently immersed in a liquid medium (salt or alkali bath) with a slightly higher or lower temperature than the upper martensite of the steel, held for an appropriate period of time. After both the inner and outer layers of the steel have reached the medium temperature, they are taken out for air cooling, and the undercooled austenite slowly transforms into martensite. Generally used for small workpieces with complex shapes and strict deformation requirements, high-speed steel and high alloy steel tools and molds are also commonly quenched by this method.

4、 Staged martensitic quenching method below Ms point

Staged martensitic quenching method with a temperature below Ms: When the bath temperature is lower than Ms of the steel used for the workpiece and higher than Mf, the workpiece cools quickly in the bath, and when the size is large, the same results as those obtained by stage quenching can still be obtained. Commonly used for large size low hardenability steel workpieces.

5、 Bainite isothermal quenching method

Bainite isothermal quenching method: The workpiece is quenched into a bath at the lower bainite temperature of the steel for isothermal quenching, so that it undergoes a lower bainite transformation. Generally, it is kept in the bath for 30 to 60 minutes. The bainite isothermal quenching process consists of three main steps: ① austenitizing treatment; ② Cooling treatment after austenitizing; ③ Bainite isothermal treatment; Commonly used in alloy steel, high carbon steel, small size parts, and ductile iron castings.

6、 Composite quenching method

Compound quenching method: First, rapidly cool the workpiece to below Ms to obtain martensite with a volume fraction of 10% to 30%, and then isothermal it in the lower bainite zone to obtain martensite and bainite structure for larger cross-section workpieces. It is commonly used for alloy tool steel workpieces.

7、 Precooling isothermal quenching method

Precooling isothermal quenching method: Also known as temperature rise isothermal quenching, parts are cooled in a lower temperature (greater than Ms) bath, and then transferred to a higher temperature bath to undergo isothermal transformation of austenite. Suitable for steel parts with poor hardenability or workpieces with large dimensions that require isothermal quenching.

8、 Delayed cooling quenching method

Delayed cooling quenching method: The parts are precooled to a temperature slightly higher than Ar3 or Ar1 in air, hot water, or salt bath, and then subjected to single medium quenching. It is commonly used for parts with complex shapes and parts with large thickness differences and small deformation requirements.

9、 Quenching and self tempering method

Quenching self-tempering method: A quenching process that heats all the workpieces to be treated, but only the parts (usually the working parts) that need to be hardened are immersed in quenching liquid for cooling during quenching. When the fire color of the non immersed parts disappears, the quenching process is immediately taken out and cooled in air. The quenching and self tempering method utilizes heat that is not completely cooled through the core to transfer to the surface, causing the surface to be tempered. Tools commonly used to withstand impact, such as chisels, punches, hammers, etc.

10、 Spray quenching method

Jet quenching method: A quenching method in which water is sprayed onto the workpiece, with a range of water flows depending on the required quenching depth. The spray quenching method does not form a vapor film on the surface of the workpiece, which ensures that a deeper hardening layer is obtained than ordinary water quenching. Mainly used for local surface quenching.

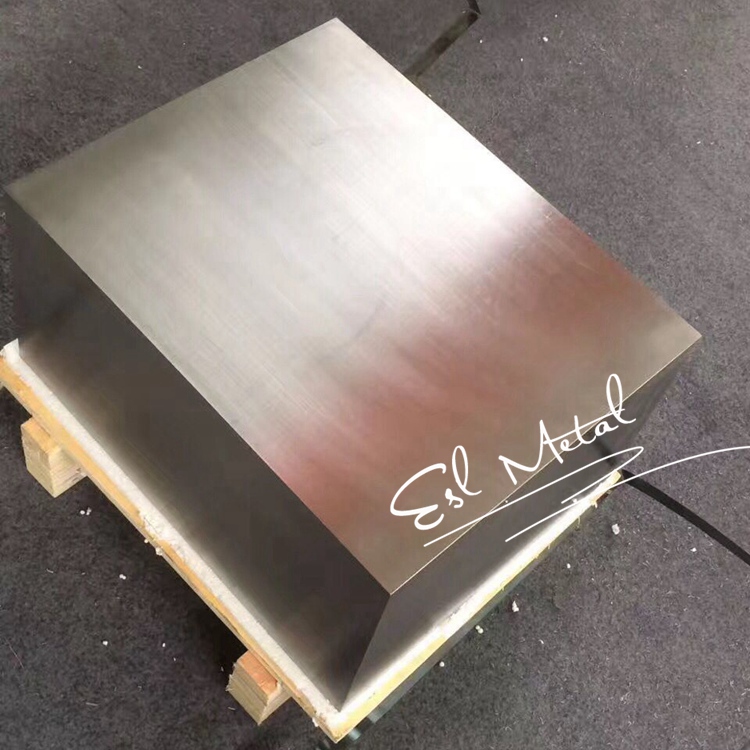

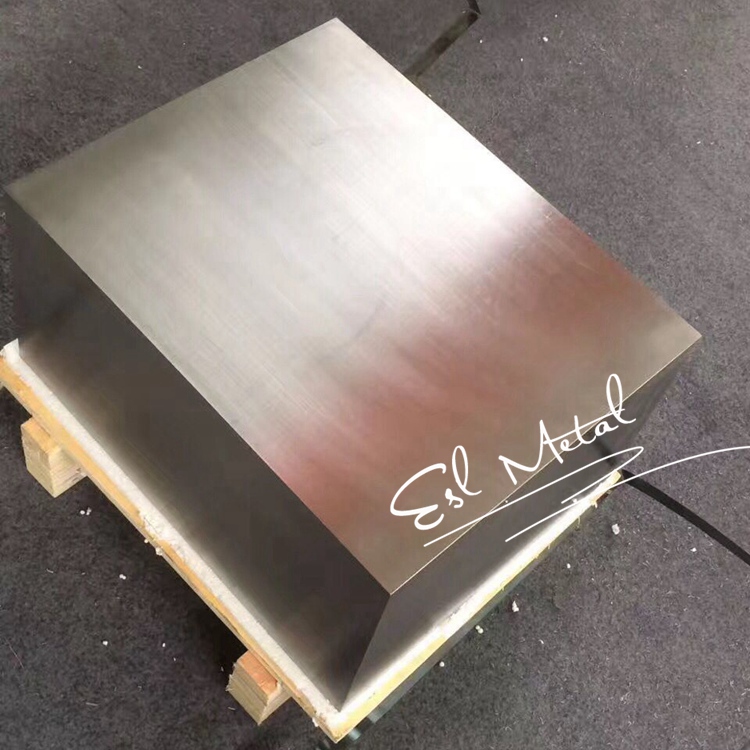

EST Metal specilize in Titanium over15 years,any inquirys welcome here.