The Comprehensive Guide to Titanium Bars and Rods

date:2024-01-24 14:16 view:

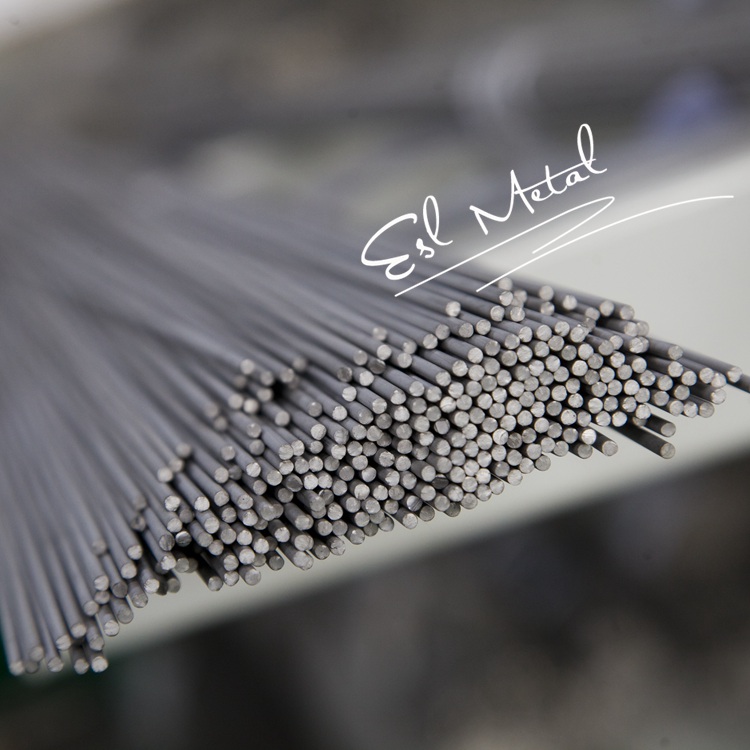

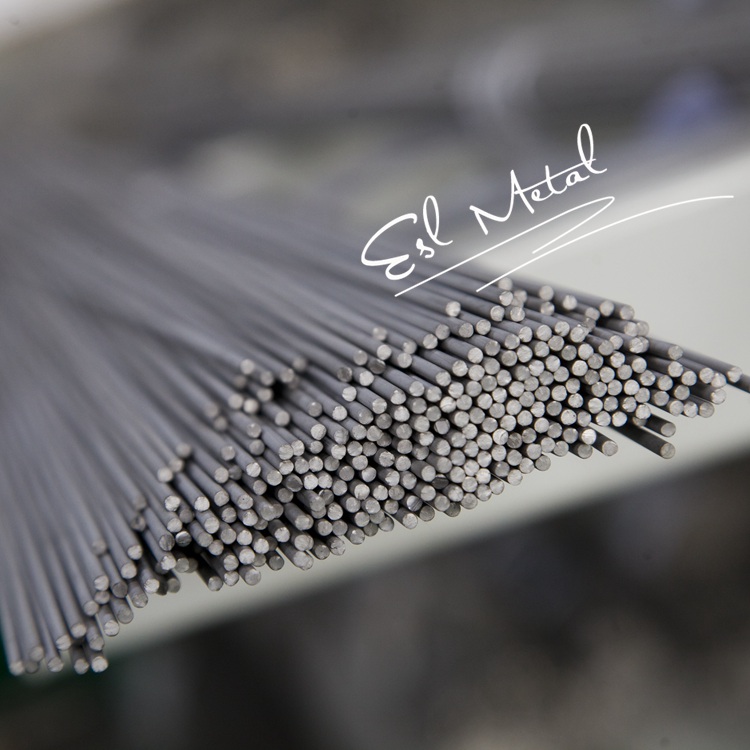

Titanium is a metal that has gained immense popularity in the industrial sector for its unique properties. It is known for its high strength, low density, and excellent resistance to corrosion. These characteristics make it an excellent choice for industries that require metal parts that can withstand harsh environments. One of the most common forms of titanium used in the industrial sector is titanium bars and rods. In this comprehensive guide, we will discuss everything you need to know about titanium bars and rods.

1. Understanding the Properties of Titanium Bars and Rods

Titanium bars and rods are made of pure titanium or titanium alloys, which are a combination of titanium and other elements such as aluminum, vanadium, and nickel. These bars and rods are known for their high strength-to-weight ratio, corrosion resistance, and excellent fatigue resistance. They also have a low modulus of elasticity, which makes them a suitable choice for industries that require lightweight and durable parts.

Titanium bars and rods are durable, lightweight, and highly resistant to corrosion, making them a sought-after material for various industrial applications. They are used in the aerospace industry, medical industry, military, and sports equipment, among others.

2. Applications and Industries Relying on Titanium Bars

Titanium bars and rods are widely used in the aerospace industry for making aircraft components such as landing gears, engine parts, and airframe components. The medical industry uses titanium bars and rods to manufacture medical implants such as artificial hip joints, dental implants, and spinal fixation devices. The military uses titanium bars and rods to manufacture lightweight armor plates, missile components, and other defense equipment.

Sports equipment manufacturers rely on titanium bars and rods to manufacture lightweight, high-strength, and durable parts for bicycles, golf clubs, and tennis rackets.

3. The Manufacturing Process of Titanium Rods

Titanium rods are manufactured using the rotary forging process, which involves compressing the metal between two rollers to form a uniform shape. The elongation and compression of the metal cause it to become stronger and denser, resulting in a titanium rod that can withstand high stress and fatigue.

Once the titanium rod is formed, it is then cut to size using a saw or shearing machine. The surface of the rod is then treated to remove impurities and improve its surface finish. The rod is also heat-treated to enhance its mechanical properties and to remove any residual stress.

4. Grades of Titanium: Choosing the Right One for Your Needs

Titanium is available in different grades, each with its unique properties and uses. The most commonly used grades of titanium are Grades 1, 2, 3, 4, 5, 7, 9, and 12.

Grade 1 titanium is the most ductile and softest grade of titanium, while grade 5 titanium is the toughest and most resistant to corrosion. The choice of grade depends on the intended use of the titanium bar or rod.

5. The Future of Titanium in Industrial Applications

The unique properties of titanium make it an attractive material for industries looking for lightweight, high-strength, and corrosion-resistant parts. The increasing demand for high-efficiency and sustainable industrial equipment is driving the growth of the titanium market.

The use of titanium in the automotive industry is expected to grow, driven by the need for lightweight and fuel-efficient vehicles. The construction industry is also expected to increase its use of titanium for its corrosion-resistant properties.

prev:Titanium Bars and Rods: Strength, Durability, and Versatilit

next:Innovations in Titanium Bar and Rod Manufacturing: Cutting-E

products

news