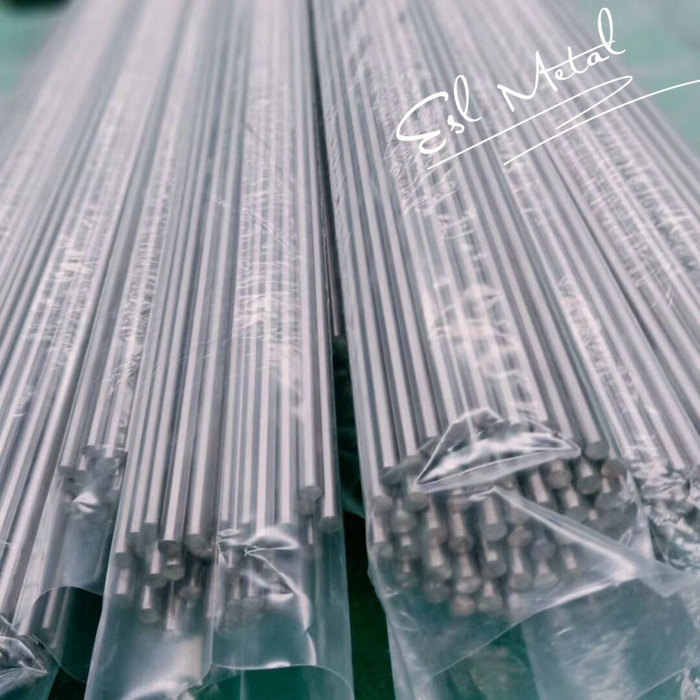

Titanium Bars and Rods: Strength, Durability, and Versatilit

date:2024-01-17 13:34 view:

When it comes to materials that symbolize strength, durability, and versatility, titanium undeniably stands out. Over the years, titanium has become a material of choice for various industries, including aerospace, engineering, medical and industrial applications. Amongst its numerous forms, titanium bars and rods are widely used for their remarkable properties and exceptional performance. In this post, we will delve into why titanium bars and rods are highly sought after, and their numerous applications across different sectors.

1.Why Titanium is the Material of Choice for Strength and Durability

Titanium is a metal that boasts incredible strength and durability. Compared to stainless steel and aluminum, titanium has a higher strength-to-weight ratio, making it an ideal material for applications that require both durability and lightness. When in the form of bars and rods, titanium is exceptionally strong and can bear significant loads without the risk of deformation or breakage. Additionally, titanium is highly resistant to corrosion, making it perfect for use in harsh environments. Its superior resistance to corrosion means it has a much longer lifespan than other metals.

2.Comparing Titanium with Other Metals in Durability

Compared to other metals, titanium has an impressive strength-to-weight ratio. Stainless steel and aluminum have densities of 8.0 g/cm³ and 2.7 g/cm³, respectively, while titanium has a density of 4.5 g/cm³. This means a titanium rod or bar of the same size and weight as an aluminum or steel one will be much stronger and more durable. Furthermore, titanium is more resistant to corrosion and can withstand extreme temperatures, thus making it an ideal material in industries like aerospace and marine.

3.Versatile Uses of Titanium Rods in Various Sectors

Titanium rods are common in various sectors like medical, chemical, aerospace, and marine. They are used in the production of orthopedic implants and surgical hardware in the medical field due to their biocompatibility properties, thus reducing surgical complications and enhancing healing. Titanium rods are common in aircraft because they meet critical strength needs demanded by today’s aircraft manufacturers. Additionally, their corrosion-resistant properties make them useful in offshore oil and gas drilling and marine shipbuilding.

4.Titanium Bars in Architecture and Construction

Titanium bars are known for their strength, which makes them a desirable material for use in architecture and construction for structural support. The strength of titanium bars is vital in design considerations to ensure that structures will withstand heavy loads and last for many years. Moreover, titanium bars are perfect for use in corrosive and harsh environments, particularly in coastal areas where salty air can quickly compromise the integrity of the structure.

As mentioned, titanium is highly resistant to corrosion, making it ideal for use in harsh environments where other metals will corrode quickly. For example, titanium alloys are useful in the manufacturing of heat exchangers in chemical plants. Harsh chemicals can quickly corrode heat exchanger materials, but the superior corrosion resistance of titanium ensures they last. In addition, titanium rods and bars are often used in desalination plants, as they can withstand the corrosive saline environment.

In summary, titanium rods and bars are incredibly durable, versatile, and strong, which is why they are highly sought after in various industries. They are uniquely suited for use in harsh environments and applications that demand a high strength-to-weight ratio. Additionally, their superior corrosion resistance properties make them the perfect material for structures, implants, and hardware that need to last for years. Therefore, it is no surprise that titanium will continue to be a popular choice for materials across various sectors.

prev:Understanding the Growing Market of Cobalt Sputtering Target

next:Working with Titanium Bars and Rods: Tips and Techniques

products

news