Working with Titanium Bars and Rods: Tips and Techniques

date:2024-01-17 13:40 view:

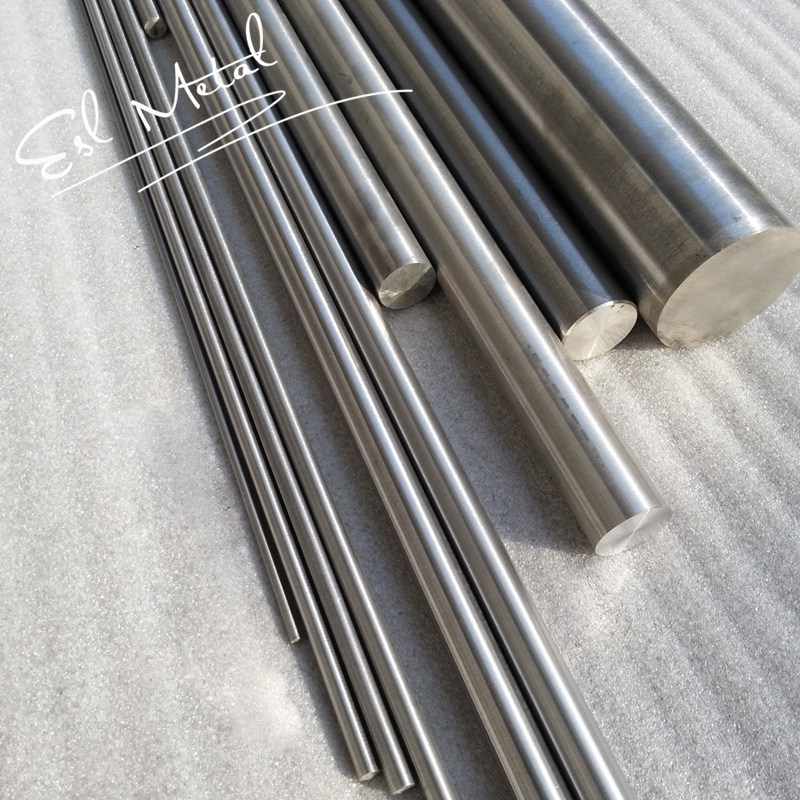

Titanium is known for its strength, durability, and high corrosion resistance, making it a popular choice for various industries. However, working with titanium bars and rods can be challenging due to its tough properties. That's why it's essential to use specific techniques for machining, welding, cutting, and shaping titanium materials. In this blog, we'll share essential tips and best practices for working with titanium bars and rods, including overcoming challenges and innovative design ideas.

1.Best Practices for Machining Titanium Bars

Machining titanium bars involve various techniques, including turning, drilling, and milling. To achieve the best results, it's essential to use appropriate tools and techniques to avoid damaging or breaking the titanium materials. Here are some best practices to keep in mind:

1. Use sharp cutting tools with custom coatings to resist heat and wear.

2. Choose the right cutting direction and speed to avoid vibration and chatter.

3. Use enough coolant or lubricant to maintain consistent temperatures and prevent workpiece deformation.

4. Maintain appropriate tool geometries and heights to prevent excessive tool wear or deflection.

2.Welding and Joining Techniques for Titanium Rods

Titanium rods can be welded, brazed, and joined using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), friction welding, exothermic welding, and electron beam welding (EBW). Here are some tips for welding titanium rods:

1. Use a pure argon or helium gas shield to prevent contamination and maintain arc stability.

2. Preheat titanium rods to reduce thermal shock and prevent thermal stresses.

3. Use filler metals with similar compositions and properties as the base metal to avoid galvanic corrosion.

4. Perform post-weld heat treatment to ensure proper metallurgical properties and reduce residual stresses.

3.Overcoming Challenges in Cutting and Shaping Titanium

Cutting and shaping titanium materials can be challenging due to their strength, toughness, and hardness. Here are some challenges and techniques for overcoming them:

1. Titanium generates a lot of heat during cutting, causing tool wear, thermal deformation, and reduced tool life. Use high-pressure coolant, and inserts with chip breakers to dissipate heat and prevent chip accumulation.

2. Titanium workpieces are prone to chatter, resulting in surface damage and reduced tool life. Use multiple inserts and reduced cutting depths to maintain stability and prevent vibration.

3. Titanium workpieces have low thermal conductivity and high thermal expansion coefficients, resulting in significant deformation during machining. Use fixtures and clamping methods to reduce deformation and maintain accuracy.

4. Titanium materials have high chemical reactivity and can react with cutting fluids and materials, resulting in carbide precipitation and surface discoloration. Use appropriate fluids, coatings, and cleaning methods to prevent chemical reactions and discoloration.

4.Safety Measures When Handling Titanium Materials

Working with titanium bars and rods involves various safety concerns due to its toxic fumes, fire hazards, and explosive properties. Here are some safety measures to follow when handling titanium materials:

1. Wear protective equipment such as gloves, goggles, respirators, and heat-resistant clothing to prevent skin contact and inhalation of toxic fumes.

2. Provide adequate ventilation to prevent the accumulation of hydrogen, which can cause explosions and fire hazards.

3. Store titanium materials in a dry, well-ventilated area away from sources of ignition and moisture.

4. Follow proper disposal methods for titanium materials, including recycling and hazardous waste procedures.

5.Innovative Design Ideas Using Titanium Bars

Titanium bars offer unique design possibilities due to their strength, durability, and visual appeal. Here are some innovative design ideas using titanium bars:

1. Titanium bars can be used for architectural applications, including cladding, roofing, railings, and sculptures, creating a futuristic and modern look.

2. Titanium bars can be used for aerospace and automotive applications, including landing gears, structural components, and engine parts, providing high strength-to-weight ratios and improved fuel efficiency.

3. Titanium bars can be used for medical and dental applications, including prosthetics, implants, and surgical instruments, due to their biocompatibility and corrosion resistance.

4. Titanium bars can be used for consumer and fashion applications, including watches, jewelry, and accessories, providing elegance and uniqueness.

Working with titanium bars and rods requires specific techniques and tools to achieve the best results and overcome challenges. From machining to welding, cutting, and shaping, following best practices and safety measures are essential for success. Furthermore, innovative design ideas using titanium bars offer endless possibilities, creating unique and elegant products across various industries. By understanding the properties and applications of titanium materials, we can unlock their full potential and create new solutions for the future.

prev:Titanium Bars and Rods: Strength, Durability, and Versatilit

next:Titanium Bars and Rods: Strength, Durability, and Versatilit

products

news